Accessories DN 25

-

System separation DN 25 (1") for HeatBloC®sFunction:

System separation DN 25 (1") for HeatBloC®sFunction:

Separation of the boiler circuit and the consumer circuit

Field of application:

for radiant panel heating systems with plastic pipes for the protection of new boilers in older heating installations

Recommended application range:

Min. residual head: 1.5 m

Temperature difference primary: 60-50 °C

Temperature difference secondary: 35-45 °C

Range of performance:

depending on the pump of the heating circuit used and the amount of plates of the heat exchanger

16 plates: up to 20 kW, 10 K up to 1720 l/h

30 plates: up to 23 kW, 10 K up to 2010 l/h

40 plates: up to 25 kW, 10 K up to 2150 l/h Learn MoreHeatBloC®

Heating

technology

Our offer is exclusively aimed at corporate clients.

-

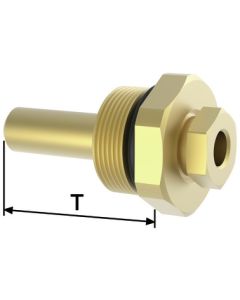

Immersion sleeves ½" ext. threadfor the installation of the temperature sensors (d = 6 mm) in the storage tank, in the collector and the hydraulic separator.

Immersion sleeves ½" ext. threadfor the installation of the temperature sensors (d = 6 mm) in the storage tank, in the collector and the hydraulic separator.

Attention: suitable for ball valves until 2016!

566001: self-sealing with, o-ring, polished brass, for sensor, T = 30 mm

566002: standard, chromed brass, for sensor, T = 60 mm

5660021: standard, chromed brass, with valve extension (25 mm), for sensor, T = 60 mm

566003: standard, chromed copper, for sensor, T = 100 mm

566004: standard, chromed copper, for sensor, T = 150 mm Learn MoreSolex|SolarBloC®

Solar

thermal

systems

Our offer is exclusively aimed at corporate clients.

-

Wall bracket DN 25 - DN 32Galvanised mounting bracket for wall assembly of HeatBloC®s.

Wall bracket DN 25 - DN 32Galvanised mounting bracket for wall assembly of HeatBloC®s.

Mount HeatBloC®s on mounting bracket for an easy assembly.

Learn MoreHeatBloC®

Heating

technology

Our offer is exclusively aimed at corporate clients.

-

Extension set for low-loss header DN 25For a subsequent conversion into a distribution manifold with integrated hydraulic separator (low-loss header).

Extension set for low-loss header DN 25For a subsequent conversion into a distribution manifold with integrated hydraulic separator (low-loss header).

Range of application up to 1600 l/h, max. up to a 3-fold distribution manifold MV3.

Consisting of two distance rings for a resistance-free connection of flow and return chamber, incl. screws and o-rings.

Learn MoreHeatBloC®

Heating

technology

Our offer is exclusively aimed at corporate clients.

-

Fitting for heat flowmeter DN 25 for unmixed HeatBloC®s- for unmixed HeatBloC®s DN 25

Fitting for heat flowmeter DN 25 for unmixed HeatBloC®s- for unmixed HeatBloC®s DN 25

- for heat flowmeters with the dimensions ¾" x 110 mm and 1" x 130 mm

Scope of delivery:

- Pump ball valve with check valve, can be opened (200 mm wc)

- Screw-in fittings

- Union nuts

- Adapter pipe

- Flange fitting

- Reducers for immersion sensor (¼" ext. thread, self-sealing x M10 x 1" int. thread and ¼" ext. thread, self-sealing x M12 x 1.5" ext. thread)

- Seals

Learn MoreHeatBloC®

Heating

technology

Our offer is exclusively aimed at corporate clients.

-

Fitting for heat flowmeter DN 25 for mixed HeatBloC®s- for HeatBloC®s DN 25 with 3-way or 4-wax mixing valve

Fitting for heat flowmeter DN 25 for mixed HeatBloC®s- for HeatBloC®s DN 25 with 3-way or 4-wax mixing valve

- for heat flowmeters with the dimensions ¾" ext. thread x 110 mm

Scope of delivery:

- Screw-in fittings

- Union nuts

- Adapter pipe

- Reducers for immersion sensor (¼" ext. thread, self-sealing x M10 x 1" int. thread and ¼" ext. thread, self-sealing x M12 x 1.5" ext. thread)

- Non-return valve for mixing valve return

- Seals

Learn MoreHeatBloC®

Heating

technology

Our offer is exclusively aimed at corporate clients.

-

Coupling piece for overhead installation DN 25Coupling piece for installation of a HeatBloC® below a distribution manifold with flat sealing.

Coupling piece for overhead installation DN 25Coupling piece for installation of a HeatBloC® below a distribution manifold with flat sealing.

Please note: When you use wall brackets, an additional mounting plate is necessary for installing a 2-fold distribution manifold MV2.

Learn MoreHeatBloC®

Heating

technology

Our offer is exclusively aimed at corporate clients.