- Best quality

- Quick assembly

- Longevity

Solex|SolarBloC®

Solar

thermal

systems

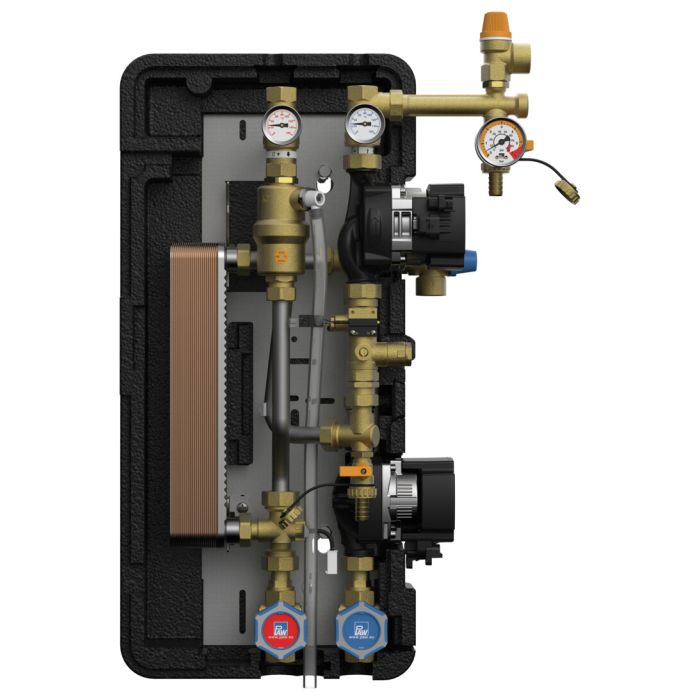

SolexMini TW up to 36 m²

Field of application: for charging buffer storage tanks

Application range: up to 36 m² collector surface

with heat quantity measurement according to the BAFA promotion directive for solar thermal systems

The CE-conformity of the installation has been certified according to DIN EN 60335.

Application range: up to 36 m² collector surface

with heat quantity measurement according to the BAFA promotion directive for solar thermal systems

The CE-conformity of the installation has been certified according to DIN EN 60335.

Operating data

Max. operating pressure primary:

6 bar

Max. operating pressure secondary:

10 bar

Max. operating temperature primary:

120 °C

Max. operating temperature secondary:

95 °C

Equipment

Controller:

SC5.14

Check valves:

primary: 2 x 200 mm wc

Pressure gauge:

0-6 bar, resistant to high temperatures

Shut-off valves:

Ball valves and piston valves

Sensors:

3 x Pt1000 (integrated) / 2 x Pt1000 (enclosed)

Safety valve:

primary: 6 bar / secondary: 10 bar

FlowRotor:

0.5-15 l/min

Airstop:

yes

Number of check valves:

2

Dimensions

Height:

681 mm

Width:

417 mm

Nominal diameter:

DN 15 (½")

Depth:

249 mm

Installation length:

686 mm

Connection primary:

¾" int. thread

Connection secondary:

¾" int. thread

Materials

Valves and fittings:

Brass

Gaskets:

EPDM / AFM34

Insulation:

EPP

Piping:

Stainless steel

Check valves:

Brass

Design data

Operating mode LowFlow:

25 l/(m²xh)

Operating mode HighFlow:

40 l/(m²xh)

Collector surface LowFlow:

36 m²

Collector surface HighFlow:

30 m²

Output LowFlow:

18 kW

Temperature difference LowFlow:

20 K

Temperature difference HighFlow:

12 K

Boundary conditions:

Irradiation = 800 W/m²; efficiency ᵑ0.05 = 65%

The compact and completely premounted solar transfer station is completely insulated and equipped with a generously dimensioned stainless steel plate heat exchanger and with a preset and prewired controller.For a simple and quick installation as well as a safe commissioning.

All connections ¾" internal thread

Premounted on steel wall bracket

can be easily mounted to the wall

All fluid-carrying parts made of brass or stainless steel, fully assembled - self-sealing or flat gaskets

Solar circuit with ball valves

key-actuated, easy handling, visible closing position, with integrated full metal thermometer 0-160 °C, can be pulled off, with immersion sleeve integrated in the ball valve, secondary circuit with piston valves

Check valve in the solar and secondary circuit, can be opened, 200 mm wc, especially for solar systems, prevent unwanted circulation

Airstop in the flow line

for permanent deaeration of the solar fluid

With high-efficiency pumps by Grundfos, premounted and prewired, adapted to the performance of the transfer station, pumps can be isolated completely, no draining during servicing

Flush and fill unit integrated

two fill and drain valves permit filling and flushing the primary circuit, secondary circuit with pressure relief valve at the highest point of the heat exchanger

FlowRotor, flow meter for speed control of the secondary pump, depending on the performance and heat quantity balancing (secondary)

Solar safety group

Solar pressure relief valve 6 bars, pressure gauge resistant to high temperatures 0-6 bars with valve, flat sealing connection for a diaphragm expansion tank, secondary side with pressure relief valve, 6 bars

Compact design insulation with optimised function

made of durable elastic EPP, 100 % insulated valves and fittings - excellent ventilation and cooling of the pumps, minimal heat losses

High-efficiency plate heat exchanger

generously dimensioned, for transmitting high performances with low temperature differences, completely integrated into the insulation

All connections ¾" internal thread

Premounted on steel wall bracket

can be easily mounted to the wall

All fluid-carrying parts made of brass or stainless steel, fully assembled - self-sealing or flat gaskets

Solar circuit with ball valves

key-actuated, easy handling, visible closing position, with integrated full metal thermometer 0-160 °C, can be pulled off, with immersion sleeve integrated in the ball valve, secondary circuit with piston valves

Check valve in the solar and secondary circuit, can be opened, 200 mm wc, especially for solar systems, prevent unwanted circulation

Airstop in the flow line

for permanent deaeration of the solar fluid

With high-efficiency pumps by Grundfos, premounted and prewired, adapted to the performance of the transfer station, pumps can be isolated completely, no draining during servicing

Flush and fill unit integrated

two fill and drain valves permit filling and flushing the primary circuit, secondary circuit with pressure relief valve at the highest point of the heat exchanger

FlowRotor, flow meter for speed control of the secondary pump, depending on the performance and heat quantity balancing (secondary)

Solar safety group

Solar pressure relief valve 6 bars, pressure gauge resistant to high temperatures 0-6 bars with valve, flat sealing connection for a diaphragm expansion tank, secondary side with pressure relief valve, 6 bars

Compact design insulation with optimised function

made of durable elastic EPP, 100 % insulated valves and fittings - excellent ventilation and cooling of the pumps, minimal heat losses

High-efficiency plate heat exchanger

generously dimensioned, for transmitting high performances with low temperature differences, completely integrated into the insulation